Understanding Polyvinyl Butyral (PVB): Properties, Applications, and Benefits

At Fait Low Price Auto Glass, we pride ourselves on providing high-quality auto glass solutions that keep our customers safe and satisfied. One essential component in modern auto glass technology is Polyvinyl Butyral (PVB). This versatile material offers numerous properties and benefits that make it an invaluable part of our industry. Whether you’re a car owner curious about what goes into your windshield or an industry professional looking to expand your knowledge, this article will provide a comprehensive overview of PVB, its properties, applications, and benefits.

What is Polyvinyl Butyral (PVB)?

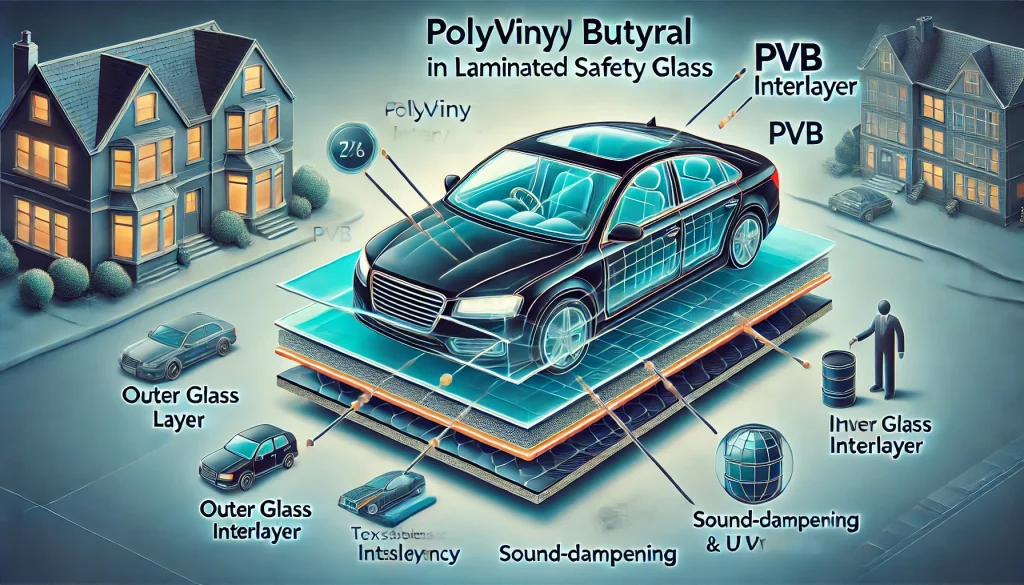

Polyvinyl Butyral (PVB) is a resin primarily used for laminated safety glass in automotive and architectural applications. This material is created by reacting polyvinyl alcohol with butyraldehyde, resulting in a strong, flexible, and transparent plastic. PVB is celebrated for its ability to bond well with glass, creating a shatterproof layer that enhances the durability and safety of the glass products it’s used in.

Properties of PVB

Understanding the properties of Polyvinyl Butyral is crucial to appreciating its role in the auto glass industry. Here are some of its most notable characteristics:

- Adhesion: PVB has excellent adhesive properties, which make it perfect for laminating with glass. This strong bond is what keeps the glass fragments together in the event of a breakage, providing a critical safety feature.

- Flexibility: Unlike many other types of plastic, PVB remains flexible over a wide range of temperatures. This flexibility ensures that laminated glass can absorb impact and resist shattering.

- Transparency: PVB is highly transparent, which is essential for maintaining the clarity of windshields and windows. This ensures that visibility is not compromised, a crucial aspect of vehicle safety.

- Sound Dampening: One of the lesser-known properties of PVB is its ability to dampen sound. Laminated glass made with PVB can significantly reduce noise, making for a quieter ride inside the vehicle.

- UV Protection: PVB can block a significant portion of ultraviolet (UV) radiation, protecting passengers from harmful UV rays and preventing the interior materials of the vehicle from fading.

Applications of PVB

PVB’s unique properties make it suitable for a wide range of applications, particularly in the automotive and architectural industries.

Automotive Applications

In the automotive industry, PVB is primarily used in the production of laminated safety glass for windshields. The inclusion of PVB in windshields provides several benefits:

- Enhanced Safety: In the event of an accident, the PVB layer helps to hold the glass together, preventing shards from scattering and potentially causing injury.

- Improved Comfort: The sound-dampening properties of PVB contribute to a quieter driving experience by reducing road noise.

- UV Protection: The UV-blocking capabilities of PVB help protect the vehicle’s occupants and interior materials from the damaging effects of the sun.

Architectural Applications

Beyond the automotive industry, PVB is also widely used in the construction of architectural glass. Some of the benefits it provides in this context include:

- Safety: Just as in automotive applications, PVB-laminated glass in buildings helps prevent injuries by holding glass fragments together in case of breakage.

- Security: Laminated glass is more challenging to penetrate than regular glass, providing an added layer of protection against break-ins.

- Noise Reduction: PVB’s sound-dampening properties are beneficial in urban environments, where reducing noise pollution can significantly enhance the comfort of building occupants.

- UV Protection: Blocking UV rays helps maintain the integrity and appearance of interior furnishings by preventing fading.

Benefits of Polyvinyl Butyral (PVB)

The numerous properties and applications of PVB translate into several tangible benefits for both consumers and industries. Let’s delve into some of these advantages:

Safety and Security

The primary benefit of PVB in laminated glass is enhanced safety. By holding glass fragments together upon impact, PVB reduces the risk of injury from flying shards. This makes it an indispensable component in automotive windshields and safety windows in buildings.

Durability and Longevity

PVB’s adhesive properties and flexibility contribute to the overall durability of laminated glass products. Windshields and windows with PVB are more resistant to impact and environmental stresses, ensuring a longer lifespan compared to non-laminated alternatives.

Acoustic Comfort

One of the standout features of PVB-laminated glass is its ability to dampen sound. Reducing noise pollution is a significant advantage, especially in urban settings or for vehicles traveling on noisy roads. This contributes to a more comfortable and serene environment inside buildings and vehicles.

UV Protection

PVB’s UV-blocking capabilities offer dual benefits: protecting vehicle occupants and building inhabitants from harmful UV radiation and preventing interior materials from fading. This not only enhances the comfort and safety of the occupants but also helps in maintaining the aesthetic appeal and value of the vehicle or building.

Energy Efficiency

In architectural applications, PVB-laminated glass can contribute to energy efficiency. By reducing the amount of UV and infrared radiation that passes through the glass, it helps maintain indoor temperatures, potentially lowering the need for air conditioning and heating. This can result in energy savings and reduced utility bills.

The Versatility of Polyvinyl Butyral (PVB)

When it comes to innovative materials in the auto glass industry, Polyvinyl Butyral (PVB) stands out due to its exceptional properties and wide range of applications. PVB’s ability to bond with glass, combined with its flexibility, transparency, sound-dampening, and UV-blocking properties, makes it an essential component in both automotive and architectural glass products. Whether enhancing safety, improving comfort, or contributing to energy efficiency, PVB plays a pivotal role in modern glass technology.

Real-World Examples and Tips

To better understand the impact of Polyvinyl Butyral, let’s look at some real-world examples and practical tips:

- Example 1: Automotive Windshields: Consider a typical car windshield. In the event of a collision, the PVB layer helps to prevent the glass from shattering into dangerous shards. Instead, the windshield may crack but will remain largely intact, thanks to the PVB layer holding it together. This not only prevents injuries but also maintains visibility until the windshield can be safely replaced.

- Tip 1: Inspecting for Damage: Regularly inspect your windshield for any signs of damage, such as chips or cracks. If you notice any issues, it’s essential to have them addressed promptly. Laminated glass with PVB can withstand minor impacts, but larger cracks can compromise its integrity.

- Example 2: Architectural Glass: In high-rise buildings, laminated glass with PVB can be used for windows and facades. This not only enhances the safety of the occupants but also contributes to the building’s energy efficiency. The sound-dampening properties are particularly beneficial in urban environments, reducing the impact of outside noise on the building’s interior.

- Tip 2: Maintenance: Regular cleaning and maintenance are necessary to maintain the benefits of PVB-laminated glass. Use non-abrasive cleaners to avoid scratching the glass and compromising the PVB layer.

Conclusion

Polyvinyl Butyral (PVB) is a versatile and essential material in the auto glass and architectural glass industries. Its unique properties, including excellent adhesion, flexibility, transparency, sound-dampening, and UV-blocking capabilities, make it a crucial component in creating safe, durable, and comfortable glass products. Whether you’re driving down the highway or relaxing in a high-rise apartment, the benefits of PVB-laminated glass enhance your safety and comfort.

At Fait Low-Price Auto Glass, we understand the importance of using high-quality materials like PVB to ensure our customers receive the best products and services. By appreciating the role of PVB in laminated glass, you can better understand the value it brings to your everyday life.

For more information on our auto glass solutions and how we incorporate advanced materials like Polyvinyl Butyral, visit our website or contact us today. We’re here to keep you safe and informed about the latest advancements in auto glass technology.